DR J P GUPTAMor

The burgeoning energy demand in our nation, propelled by its growing economy, currently witnesses approximately 98 per cent of the transportation sector’s fuel needs being fulfilled by fossil fuels, while the remaining 2 per cent is sourced from biofuels.

Attaining energy security and pivoting toward a flourishing low-carbon economy stand as critical imperatives for a nation such as India. Renewable ethanol emerges as a catalyst for a net reduction in CO2 emissions, carbon monoxide, and hydrocarbons (HC). Notably, ethanol combustion demonstrates superior cleanliness and completeness compared to petrol. The imperative for biofuel production to escalate by an average of 11 per cent annually throughout this decade, as outlined by the International Energy Agency, remains crucial in steering the globe towards a netzero trajectory.

To facilitate this growth, the Global Biofuel Alliance has set its targets. Ethanol presents a low-carbon alternative to fossil fuel-based transportation, spanning from gasoline to aviation turbine fuel. Bio-ethanol, an agricultural by-product derived from processing sugarcane, cane juice, and molasses, undergoes fermentation to yield ethanol. Additionally, ethanol production extends to grains, broken rice, maize, and agricultural residues like rice husk and stubble. Technologies applied to ethanol production span across distinct generations, encompassing 1G, 1.5G, and 2G methodologies. The blending of bio-ethanol with petrol has stood as a flagship initiative under Prime Minister Narendra Modi’s government since 2014.

The programme’s resounding success manifests in the escalating blending percentage, surging from 1.6 per cent in 2013 to nearly 12 per cent by 2023. In absolute terms, the initial blending of 38 crore liters of alcohol burgeoned to approximately 470 crore liters in 2023. With an eye on the future, the government has unveiled a roadmap targeting a blend of up to 20 per cent ethanol in petrol by 2025–26, underlining the necessity for a nationwide production capacity of up to 1,500 crore liters of ethanol.

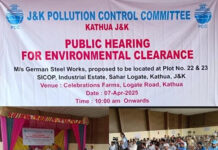

This pioneering programme not only champions the use of renewable fuels but also curtails greenhouse gas emissions while fortifying energy security. The government’s expeditious advancement of the blending programme, via streamlined environmental clearances and backing through tax credits, subsidies, and financial incentives for biofuel producers and distributors engaged in ethanol blending, reflects an Indiacentric energy trajectory, reliant on local raw materials, technologies, and plant machinery.

Furthermore, the government guarantees ethanol purchase by Public Sector Undertakings (PSUs), ensuring a secured off-take. This has unlocked avenues for profitable enterprises and catalyzed the establishment of biorefineries across the nation, luring in billions of rupees in investments, fostering ethanol distilleries across nearly every district in India. Ethanol, blendable up to 85 per cent with gasoline, finds common usage in Flexible Fuel Vehicles (FFVs) engineered to function optimally with ethanol blends.

FFVs are equipped with specialized engine and fuel system components to accommodate higher ethanol concentrations.

Ethanol amplifies octane ratings, curtails dependence on fossil fuels, and diminishes greenhouse emissions, thus nurturing energy sustainability and security. Most distilleries in the country primarily produce bio-ethanol from C-heavy molasses, Bheavy molasses, or cane sugar. However, alternate feedstocks like food grains, broken rice, corn, etc., are gradually gaining traction.

These stocks are transformed into sucrose, glucose, and fructose, which are subsequently fermented into ethanol utilizing yeast. The government’s practice of offering higher prices for ethanol produced from certain feedstock, such as anything other than C-heavy molasses, lacks a rational basis. Ethanol producers should have the autonomy to select technologies and feedstock based on economic viability. The pricing framework requires rectification to ensure a level playing field.

A recent governmental policy announcement imposing restrictions on cane juice utilization for ethanol production has unsettled bioethanol producers. This move appears to signal a slowdown in ethanol blending due to dwindling sugar stocks. Instead of an outright ban on ethanol production from sugar, the government could have explored options such as sugar imports, analogous to stockpiling cooking oil and onions during scarcity.

A flagship initiative like ethanol blending, with its unequivocal success, should encounter minimal hindrances on its path to realizing its full potential. Additionally, billions of rupees invested in distilleries currently hang in uncertainty. Capitalizing on abundant biomass resources as feedstock for Compressed Bio-Gas (CBG) plants could catapult India toward an impressive daily CBG production capacity of 170,000 MT.

This surge could potentially supplant one-third of crude oil imports or triple the imported LNG. The government has recognized the potential of biogas generation, given the livestock population of 536 million. The government’s policy document spanning from 2021- 2022 to 2025-2026 underscores this pursuit. Biogas, comprising approximately 55-65 per cent methane, 35-44 per cent carbon dioxide, and traces of Hydrogen Sulphide, Nitrogen, and Ammonia, can serve as a substitute for LPG. Cow dung and organic waste serve as primary sources for biogas generation.

The government’s annual budget outlay of Rs. 858 crore encompasses Rs. 100 crore dedicated to small plants (generating 1 m3 to 25 m3 biogas per day) and mediumsized biogas plants (ranging from 25 m3 to 2500 m3 biogas per day and within the spectrum of 3 kW to 250 kW biogas for thermal/cooling energy). Building upon the triumph of the ethanol blending programme, the Government of India proposed the establishment of a Global Biofuel Alliance during the G20 summit. Led by nations within the G20 like India, Brazil, and the US, along with 12 international organizations, the Global Biofuel Alliance aims to channel technology investments, foster expert collaboration, and set global standards to diminish reliance on hydrocarbons.

Bio-ethanol, biodiesel, and Aviation Turbine Fuel are slated to supplant fossil fuels. Biofuels, derived from renewable sources like vegetable oils and animal fats, emerge as cleaner alternatives to traditional diesel and can be blended with petroleum diesel in varying ratios. The Global Biofuel Alliance pledges support for second-generation (2G) ethanol crafted from agricultural waste, used cooking oil, and processed animal byproducts like fats. Presently, India’s biofuel market encompasses 230 biomass pellet manufacturers and 1,030 briquette manufacturers, catering to power plants and industries.

Bolstered by investments from global green energy entities and governmental initiatives, the Indian biomass market is poised to reach INR 320 billion by the fiscal year 2030-31. Given the substantial growth potential of biofuels and compressed biogas, unwavering government policies stand as an imperative. These policies can substantially curtail India’s reliance on imported fossil fuels, resulting in reduced carbon emissions.

Recognizing the significance of biofuels and compressed biogas, coupled with the unwavering support provided by the government in this sector, it becomes indispensable for the government to ensure the consistency of policies.

(The writer is Managing Director, Greenstat Hydrogen India Pvt. Ltd., and Chairman, Environment & Green Hydrogen Committee, PHD Chamber of Commerce & Industry, New Delhi. He can be reached at jpglobalconsultinggroup@gmail.com)